What is Bio-oil?

Bio-oil is a liquid fuel derived from biomass through the process of pyrolysis (thermal decomposition in the absence of oxygen). It is a dark brown, viscous liquid containing hundreds of organic compounds and water.

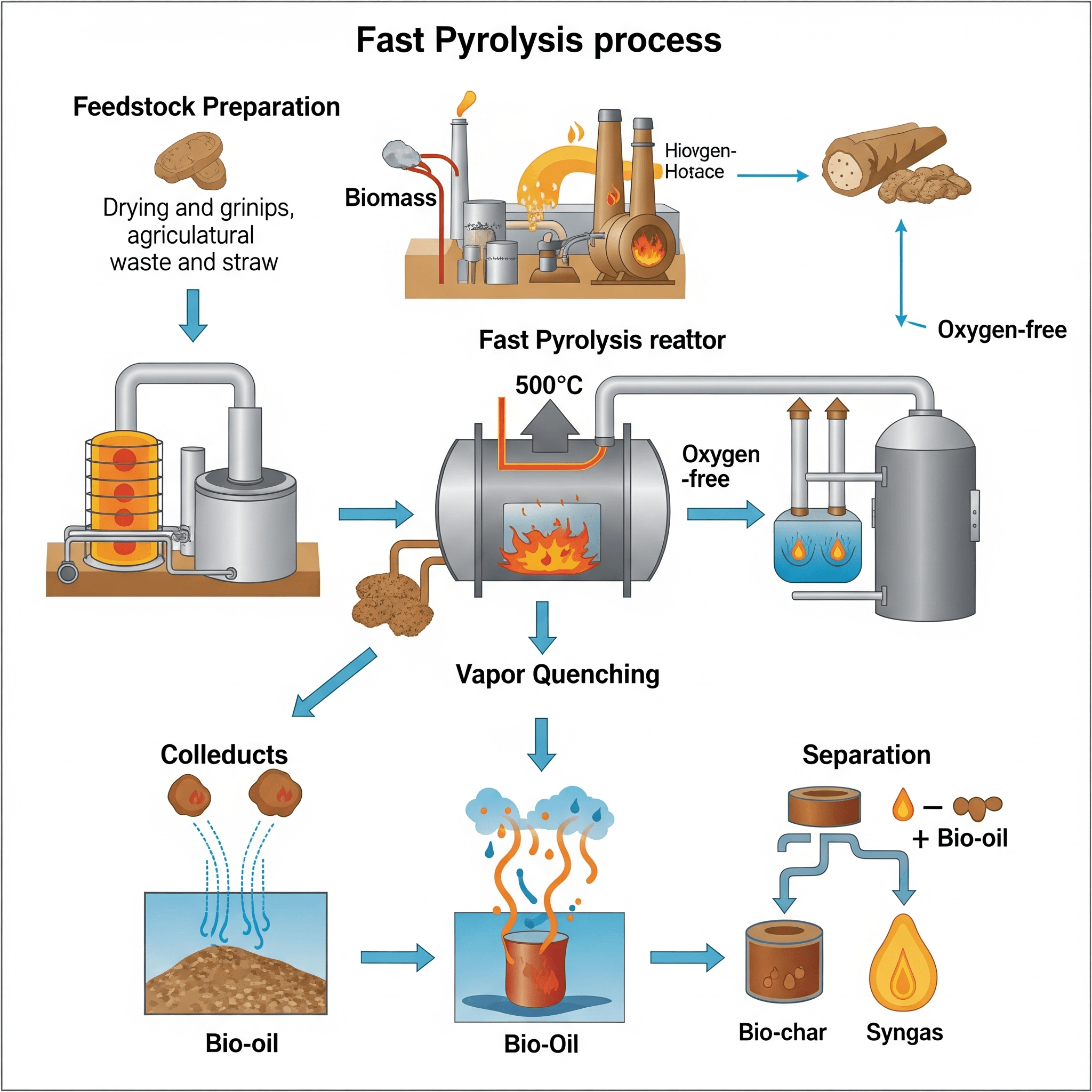

Production Process: Fast Pyrolysis

What is Pyrolysis?

- Pyrolysis is the process of thermally degrading biomass at 300–600°C in the absence of oxygen.

- Fast pyrolysis is preferred for bio-oil production because it maximizes the yield of liquid products.

➤ Steps:

- Feedstock preparation: Biomass (wood chips, agricultural waste, straw) is dried and ground.

- Fast Pyrolysis Reactor: Heated rapidly to 500°C in an oxygen-free environment.

- Vapor Quenching: The hot vapors are quickly cooled to produce liquid bio-oil.

- Separation: The bio-oil is collected; bio-char and syngas are separated as co-products.

Properties of Bio-oil

|

Property |

Description |

|

Appearance |

Dark brown, viscous liquid |

|

Energy content |

16–19 MJ/kg (lower than petroleum) |

|

pH |

Acidic (pH 2–4) |

|

Water content |

15–30% |

|

Density |

1.1–1.3 g/cm³ |

|

Stability |

Thermally and chemically unstable |

|

Oxygen content |

High (~35–40%) |

Feedstocks for Bio-oil Productionleke

- Wood chips

- Agricultural residues (wheat straw, rice husk, sugarcane bagasse)

- Forestry residues

- Energy crops (switchgrass, miscanthus)

- Organic municipal solid waste

Advantages of Bio-oil

- Renewable and sustainable

- Utilizes agricultural/forestry waste

- Can be burned for heat or electricity

- Can be upgraded to transportation fuels

- Carbon-neutral (biomass reabsorbs CO₂ during growth)

- Contains less sulfur and nitrogen than fossil fuels

Limitations of Bio-oil

- Low heating value compared to fossil fuels

- High water and oxygen content reduce combustion efficiency

- Corrosive and unstable during storage

- Requires upgrading (hydrotreating) for use in engines

- Viscous and may need preheating

Upgrading of Bio-oil

To be used as a transportation fuel, bio-oil must undergo:

- Hydrotreating: Removes oxygen using hydrogen

- Catalytic cracking: Breaks down large molecules

- Emulsification: Mixed with diesel for fuel blends

Applications of Bio-oil

- Energy and Heating; Can be burned in boilers and furnaces for heat and power generation

- Industrial Use; As a feedstock for chemicals and resins, Carbon black production

- Transport Fuels (after upgrading) Can be upgraded into diesel or gasoline substitutes

- Chemical Industry; Source of phenols, acetic acid, furfural, etc.

Environmental Impact

- Reduces waste by using agricultural residues

- Carbon-neutral fuel

- Low NOx and SOx emissions

- May emit VOCs if not properly burned or stored

Bio-oil vs. Biodiesel vs. Petroleum

|

Feature |

Bio-oil |

Biodiesel |

Petroleum Diesel |

|

Source |

Biomass (via pyrolysis) |

Vegetable oil (via transesterification) |

Fossil fuel |

|

Energy content |

Low (16–19 MJ/kg) |

Medium (~37 MJ/kg) |

High (~45 MJ/kg) |

|

Stability |

Low |

High |

High |

|

Oxygen content |

High |

Low |

Very low |

|

Water content |

High |

Low |

Very low |

|

Use in Engines |

Needs upgrading |

Direct use (B20/B100) |

Direct use |

Future Prospects

- Research on stabilizing bio-oil for direct engine use

- Co-firing bio-oil with coal in power plants

- Decentralized pyrolysis units near biomass sources

- Development of integrated biorefineries

- Focus on bio-oil from algae and municipal waste