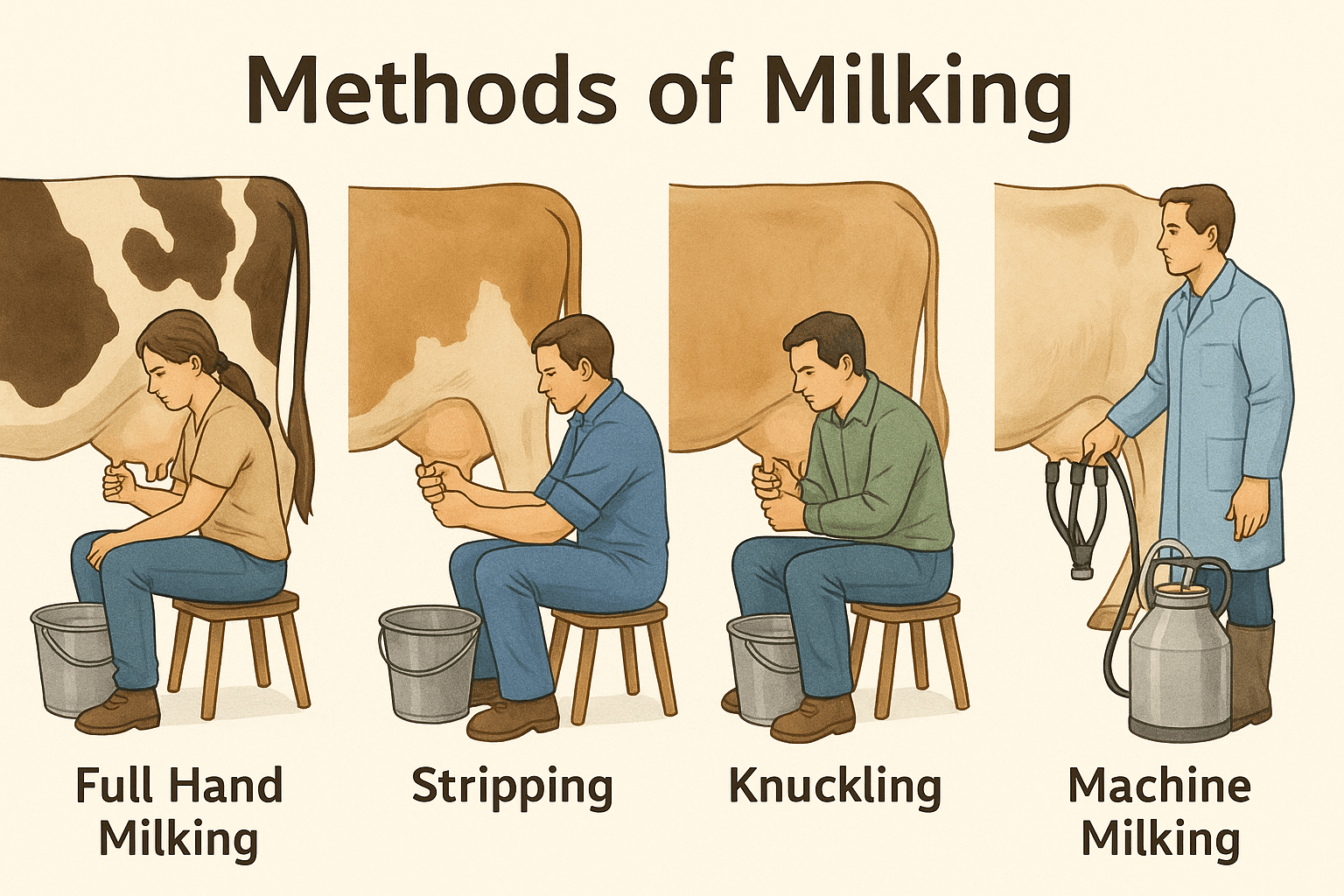

Methods of Milking; Milking is the process of extracting milk from the mammary gland (udder) of dairy animals. Efficient milking ensures good milk yield, udder health, and hygiene.

🔹 1. Hand Milking

a) Full Hand Milking (Recommended Method)

- The entire hand (fingers and thumb) is used to press the teat from top to bottom.

- Milk is squeezed out, not pulled.

- Prevents injury to teats and udder.

- Advantages:

- Hygienic

- Comfortable for animal

- Recommended for buffaloes and cows

b) Stripping

- Milk is pulled down by sliding fingers from top to bottom.

- Not recommended due to risk of teat injury.

- Used only to empty residual milk after normal milking.

c) Knuckling

- Teat is pressed using finger joints (knuckles).

- Harmful: May damage teat canal and lead to mastitis.

- Not advised.

2. Machine Milking

- Used in commercial dairy farms with large herd size.

- Works on vacuum and pulsation principle.

- Mimics suckling of calf by creating intermittent vacuum and release.

3. Wet vs. Dry Milking

|

Type |

Description |

|

Dry Milking |

Milking without applying water to teats. Most hygienic. Recommended. |

|

Wet Milking |

Teats washed immediately before milking without drying. Not recommended due to risk of contamination. |

🔹 Milking Principles

- Follow regular timing (interval of 12 hrs).

- Ensure clean hands and utensils.

- Start milking soon after let-down reflex (oxytocin release).

- Avoid stress to the animal.

- Strip the teats to check for mastitis.

Key Points for Exam

- Best method: Full-hand milking

- Machine milking: Based on vacuum principle

- Harmful method: Knuckling

- Let-down reflex: Stimulated by oxytocin

- Dry milking is more hygienic than wet milking

Thermal Processing of Milk

Purpose of Thermal Processing

- Most heat-resistant pathogen: Bacillus tuberculosis (Index organism).

- Key pathogens in milk: Tubercle bacilli, Typhus, Coliforms, Coxiella burnetii (Q-fever).

Types of Heat Treatments

|

Treatment |

Process |

Temperature (°C) |

Time (seconds) |

|

Pasteurization |

LTLT |

63 |

1800 Sec. (30 min) |

|

HTST (milk) |

72 |

15–20 |

|

|

HTST (cream) |

>80 |

15 |

|

|

Thermization |

– |

57–68 |

15 |

|

Sterilization |

– |

115–121 |

180–780 (20–30 min) |

|

Ultra-pasteurization |

– |

115–130 |

2–4 |

|

UHT |

– |

135–150 |

1–6 |

- Pasteurization

Definition: Heat treatment of milk to kill pathogens without affecting nutritional quality, followed by rapid cooling and refrigeration.

Types:

- LTLT (Low Temp Long Time):

- Temp: 63°C

- Time: 30 min

- Method: Batch process in jacketed vats (200–1000 L capacity)

- Suitable for: Small-scale operations

- HTST (High Temp Short Time):

- Temp: 72°C

- Time: 15 seconds

- Method: Continuous flow in plate heat exchangers

- Suitable for: Large-scale (≥5000 L/hr)

🔹 2. Thermization

- Purpose: Temporary heat treatment when immediate pasteurization isn’t possible.

- Temp: 63–65°C

- Time: 15 sec

- Benefit: Inhibits bacterial growth; spores revert to vegetative form for later destruction in pasteurization.

- Ultra-pasteurization

- Temp: 115–130°C

- Time: 2–4 sec

- Shelf life: Extended by 15–30 days

- Requires: Aseptic packaging, strict hygiene, cold storage (<4°C)

- Ultra High Temperature (UHT)

- Temp: 135–150°C

- Time: 1–6 sec

- Method: Direct (steam injection) or Indirect (heat exchangers)

- Aseptic packaging: Special multilayer containers

- Shelf life: 2–6 months without refrigeration

- Sterilization

- Temp: 115–121°C

- Time: 20–30 min

- Containers: Glass bottles or tin cans (200–400 g)

- Method: In-container (batch or continuous via autoclaves/hydrostatic towers)

- Result: Kills all microbes including spores.

- Microwave Heating

- Frequency: 915 or 2450 MHz

- Mechanism: Water dipole oscillation produces heat internally

- Benefits:

- Fast, uniform heating

- Reduced lag in heat penetration

- Challenges:

- Surface cooling due to evaporation

- Uneven absorption in frozen or high-salt foods

✅ Important Points to Remember

- Bacillus tuberculosis: Index organism for pasteurization.

- HTST is energy-efficient due to regeneration.

- Thermization is pre-treatment before pasteurization.

- UHT milk needs no refrigeration.

- Sterilization gives longest shelf life but may alter taste.

- Microwave heating is rapid but less uniform.